Latest News

A temperature control system installed with Johnson Brewing Design Ltd at Marble Brewery, Manchester. Please read the article published in SIBA Journal in October 2014 - Get Smart with Johnson's SMART BREW

Johnson Brewing Design Ltd has been developing a new system for the temperature control of FVs, CTs and other brewery vessels, called SMART BREW.

The company has been incorporating temperature control systems in its brewery installations for many years. Over time these have got better by introducing accurate electronic display contollers and illuminated feedback control to verify automatic valve position. However, Johnson wanted to develop a system that was commercially affordable, giving the brewery the same in-house control but with a number of added benefits, such as real-time logging of temperature per tank with historical recording, option to fit level sensors and also remote access. It's time consuming and labour-intensive to have staff attending site over the weekend for FV temperature checks or to make sure the FLT is up to temperature for Monday morning. So with modern technology available and so many people people operating

Johnson Brewing Design Ltd has been developing a new system for the temperature control of FVs, CTs and other brewery vessels, called SMART BREW.

The company has been incorporating temperature control systems in its brewery installations for many years. Over time these have got better by introducing accurate electronic display contollers and illuminated feedback control to verify automatic valve position. However, Johnson wanted to develop a system that was commercially affordable, giving the brewery the same in-house control but with a number of added benefits, such as real-time logging of temperature per tank with historical recording, option to fit level sensors and also remote access. It's time consuming and labour-intensive to have staff attending site over the weekend for FV temperature checks or to make sure the FLT is up to temperature for Monday morning. So with modern technology available and so many people people operating

smart phones or tablet computers, Johnson set out to make the new system to be not only viewed but controlled from the operator's chosen device.

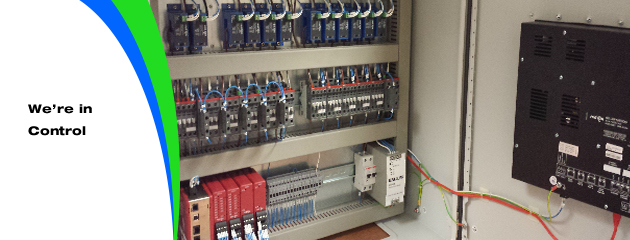

The new system has been developed in collaboration with Retro Control Ltd who build the control equipment, interpreting operating philosophies into hardware. With the system it is possible to connect to your control panel in the brewery from any device connected to the internet.

Once connected it is as good as being physically stood in front of the control panel.

There is an overview page, which displays all the tank temperatures on one screen and also gives the valve status (open/closed) per tank. It is then possible to click or touch

The new system has been developed in collaboration with Retro Control Ltd who build the control equipment, interpreting operating philosophies into hardware. With the system it is possible to connect to your control panel in the brewery from any device connected to the internet.

Once connected it is as good as being physically stood in front of the control panel.

There is an overview page, which displays all the tank temperatures on one screen and also gives the valve status (open/closed) per tank. It is then possible to click or touch

any tank on the screen. This will take the user to the individual tank screen where it is possible to adjust the set point of the temperature or manually operate the valve from a device. From this screen you can connect to the trend data screen that has recorded the temperature over the pre-set time and if fitted check the level in the tank.

It is also possible in some instances to view and control the hot liquor tank temperature or any other electrical equipment once connected to the SMART BREW system. It is important to mention that this system still requires the usual chiller unit and pipe work that would be installed on a standard system.

It is also possible in some instances to view and control the hot liquor tank temperature or any other electrical equipment once connected to the SMART BREW system. It is important to mention that this system still requires the usual chiller unit and pipe work that would be installed on a standard system.